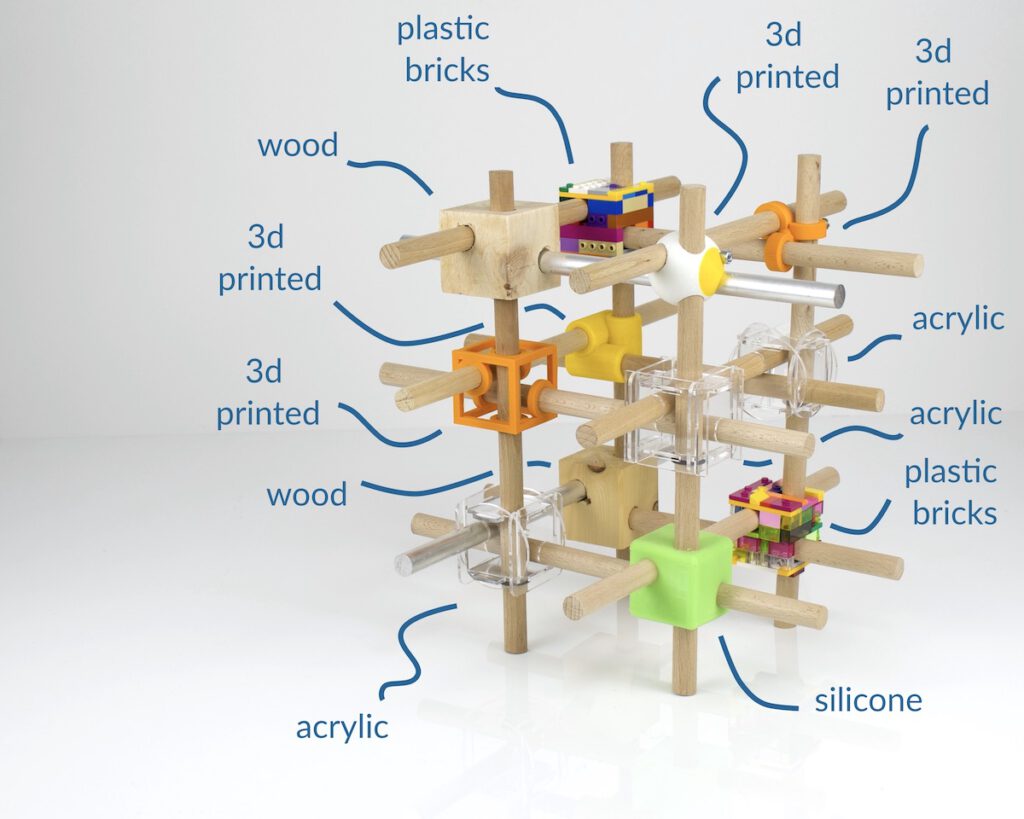

Ikego Part Design Suggestions

Vs. 1.1

How to find or design multipurpose parts that can creatively reused by others?

.

Some suggestions

.

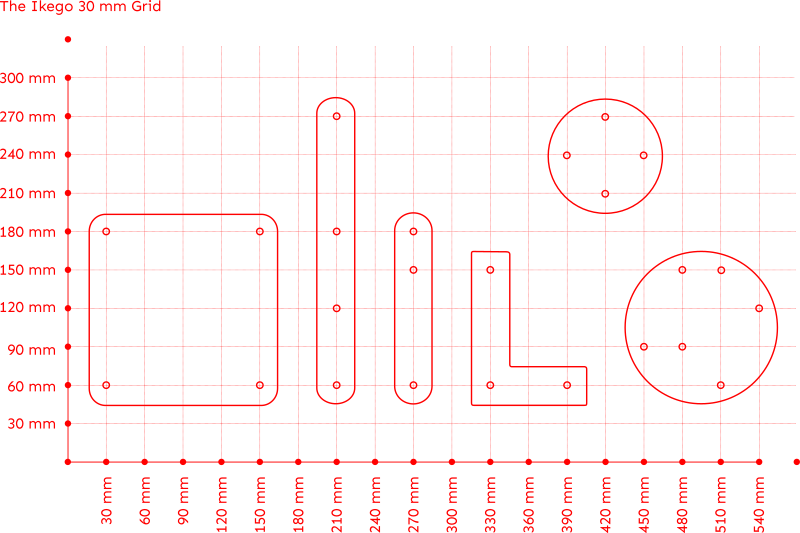

1 A Shared Grid – the Ikego Grid

Erector sets are a good example of multipurpose parts.

All parts of an erector set fit together with all other parts. This works because the parts are based on the same grid – the distance between the holes for the nuts and bolts is always the same in all the parts. When you add a new part, just follow this grid and the new part can be married to all the other parts in an infinite number of ways.

So if you want to design a part for multiple purposes, look for a grid that already exists and has lots of parts to connect to. Ikego suggests a grid of 30mm between two holes.

The Ikego grid uses a 30mm grid. Obviously, unlike the toys, not every possible hole is drilled, just the ones needed for this part’s known uses. If you are interested in the origin of the Ikego 30mm grid, read here & here.

The Ikego Grid is a suggestion. It is not mandatory, if you want to share your design here on Ikego. But it will allow you to connect to many other parts from the Ikego parts catalog. But feel free to plug in other grids.

.

2 Tolerance → local reuse, repair and manufacturing

Ideally, an open multipurpose part will allow local manufacture – even in small workshops. So ideally, for most applications, the part is relatively independent of the material you make it from, and also allows for some inaccuracy in the dimensions of the manufactured part. This is what we call “tolerance”.

Why “material” tolerance? → Because it allows the use of local or leftover material. And also a designer’s creative expression when picking out the final materials and colors.

Why size tolerance? → Because it allows the use of simple tools that are available everywhere. If you need a heavy, expensive machine capable of producing 0.1mm accuracy to make your part work, local manufacture is difficult to achieve, which will make repair or reuse a bit harder. The standard tolerance allows a size deviation of +/- 15mm from the values mentioned in the parts post.

Examples ↓

✼

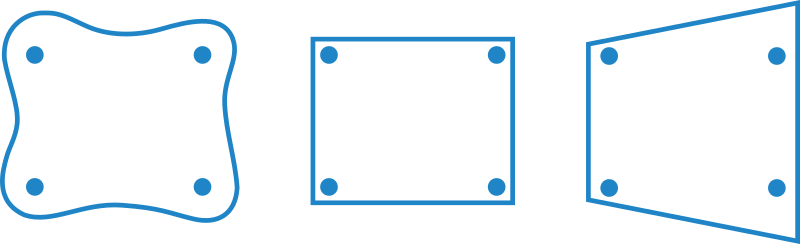

It is important to understand that the number, position and diameter of the holes are not affected by the tolerance! The holes and their exact position in relation to each other make up the identity of the part. Because this is how the parts connect to each other within a grid.

These parts are all the same

The outer shape varies slightly, but the holes are the same size and in the same position relative to each other.

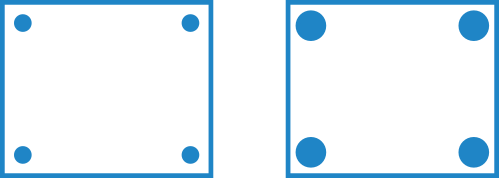

These parts are different

Same board size, same position of holes in the grid, but the holes are of a different size.

Different parts

These are two different parts. The dimensions are the same and the holes are in the same location, but the holes are different in size.

Same parts

These are the same parts. The dimensions are slightly different but the location of holes relative to each other and their diameters are exactly the same.

✼

Tolerance is a running experiment! We are aware that tolerance may lead to cases where a part does not work in a design with that part (for example when the material is too weak or parts overlap). Le’s see if this really emerges and how big an issue it will be. Ikego is open research. Research with us.

Tolerance enables creative expression. A model is set but the final curves, colors and materials are decided by the designer.

_

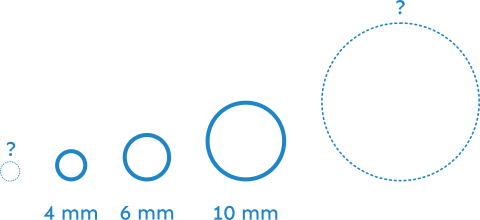

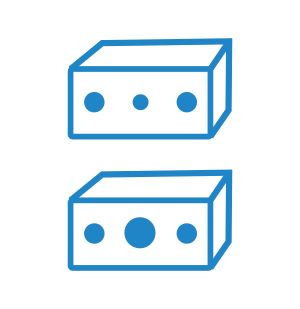

3 Bolt sizes & Hole sizes

The tolerance rule explains why bolts come in these steps:

10 – 30 – 50 – 70 – 90 – 110 – 130 – …

+/- 15mm allows to have all steps in between – for example 14mm.

heads of bolts are free to chose (tolerance)

So far, Ikego designers have worked with 3 different hole & bolt sizes:

10mm – for structures that need to be really strong or to cover M6 cap nuts.

6mm – for M6 screws that are strong enough for furniture such as beds or chairs

4mm – for M4 bolt solutions such as headphones, rucksacks and other small items that don’t need to support a lot of weight.

But this is just a suggestion. Feel free to step out of this.

*

What are ‘makes’?

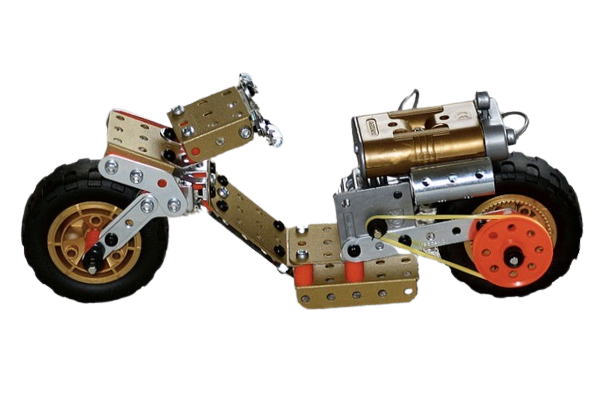

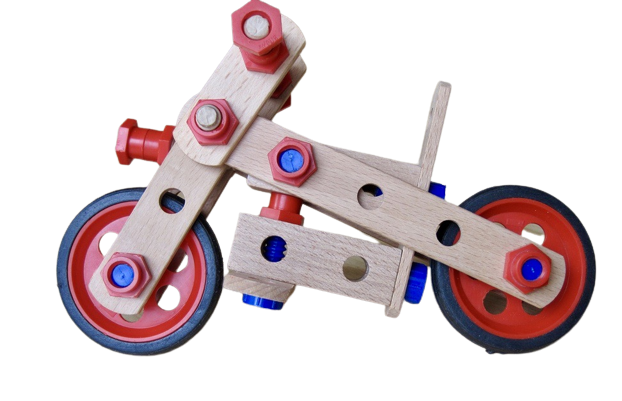

An Ikego model is a group of multipurpose parts that can be assembled into a functioning solution. The parts are open source and can be made in different materials and even dimensions (see tolerance ↑). This means that the same Ikego model can look very different depending on the materials, colors, curves and finishes chosen by a maker or manufacturer. The same chair can be made of cardboard, plastic or metal, in black with rounded corners or in yellow with sharp edges and so on. But the parts are interchangeable between all chairs.

→ Call for makers!

A functional prototype is required to include a model in the Ikego catalog. But the final design decisions (colors, materials, curves) are made by the maker. Show us your interpretation of a model!

\(◎o◎)/

call for makers

Set stats: Prototype, make, product?

Ikego sets evolve in 3 different variants:

Prototype – a rough functional prototype that proves that a model works; required to include a solution in the catalog | see design brief

Make – a well-made execution (‘interpretation’) of a model by a skilled craftsman, add a make | see call for makers

Product – a professional make that is intended to be sold to customers for money | see manufacturer brief