BOLTS & Grid

How to invent universal parts?

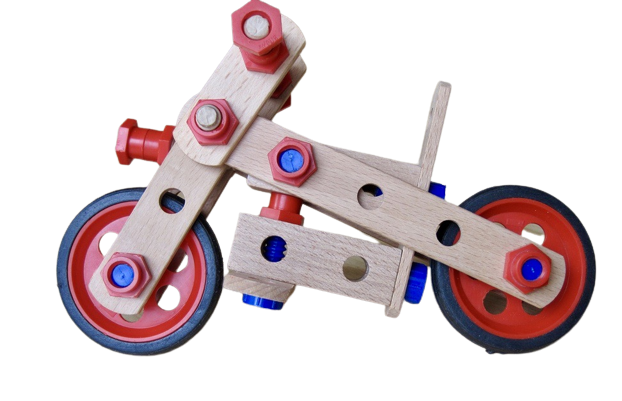

Ikego system version 1

Ikego parts can be creatively recombined, because most are based on a shared grid.

CLICK to learn more about ∷ TH3 GRID

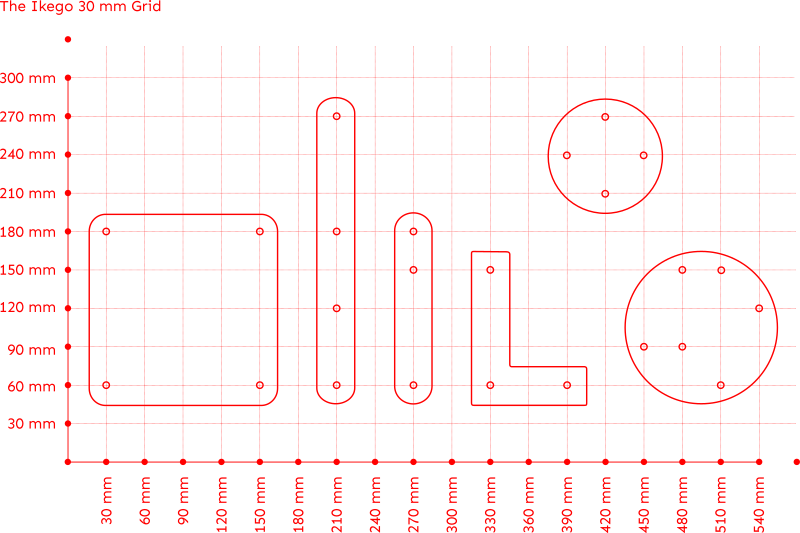

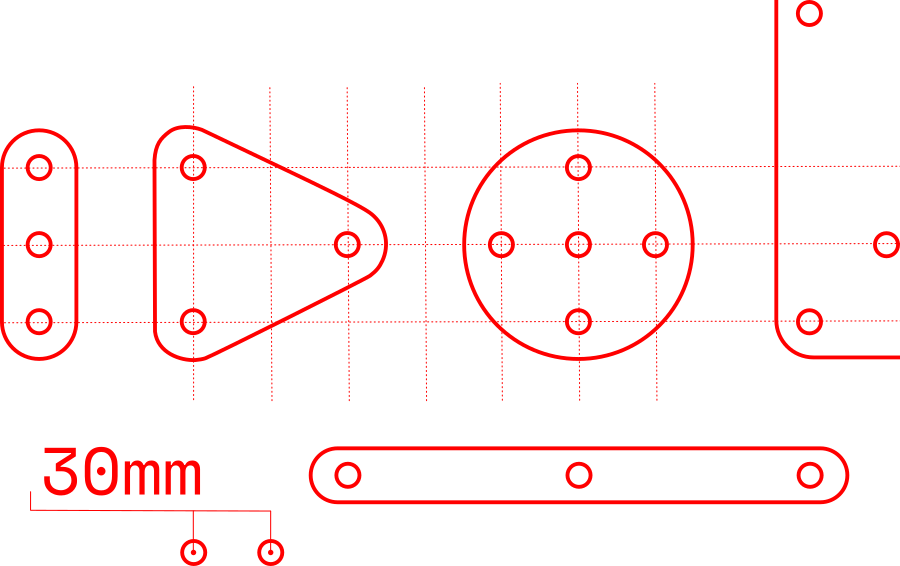

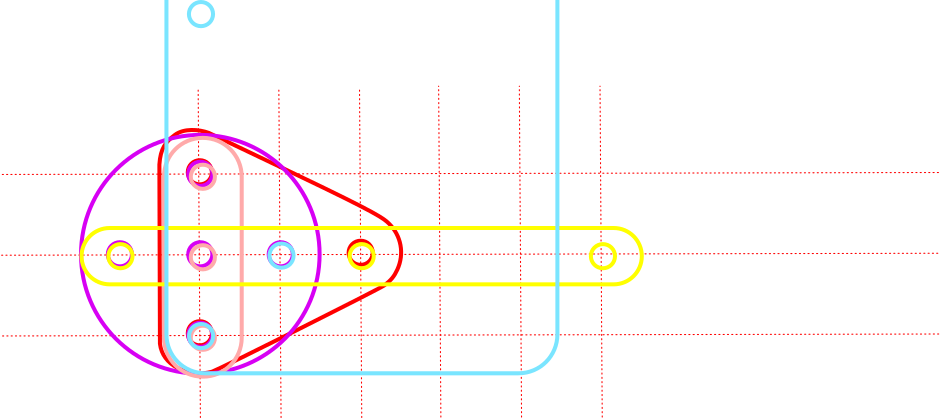

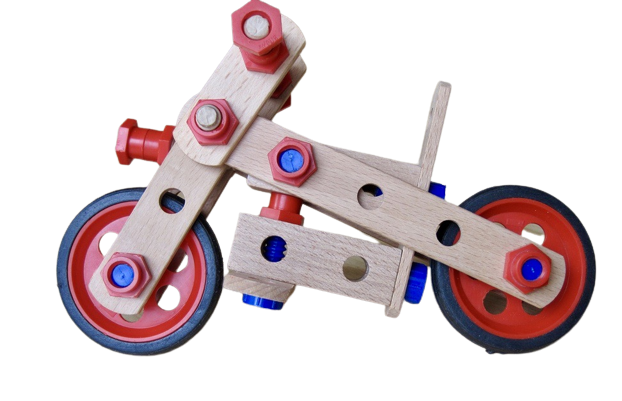

The inspiration for this is drawn from erector sets. In an erector set all parts fit together because they are based on the same grid – the distance between the holes for the nuts and bolts is always the same. Ikego uses this principle. The Ikego-Grid uses distance of 30mm:

Follow the grid when you need to add a hole. But you don’t have to drill all the holes that are possible, just the ones needed for this part’s known uses.

The Ikego Grid is just a suggestion for designers. It is not mandatory if you want to add new parts to Ikego. But it will allow you to connect to many other parts from the Ikego parts catalog. But feel free to plug in other grids.

If you are interested in the origin of the Ikego 30mm grid, read here & here.

✼

30mm distance; connecting holes always meet

Connections are made with reuseable fasteners, making ♾️ disassembly and reassembly easy.

Yes! It works basically like a construction toy for kids 🔩🧒, but grown and extended in infinite ways 🍄🪸🟫 and used for real world solutions 🥁🪑🛋️🚒🚄🛰️.

A super capable system to (re)build anything!

iŋ

↓

3voluti0n

We believe that a system of super universal parts cannot be planned by a single individual or just a small group of people. It needs to emerge through constant evolution, experimentation and collaboration by many. Play with us. B3 TH3 S0UP! 🦠

SOUP? Why SOUP? And how is it made? Click here

⊹

The world is infinitely complex, and a single brain has only limited bandwidth. We need the “wisdom of the crowd” to discover truly universal parts:

To drive discovery, we constantly add new parts and enter them into an ‘evolutionary’ race.

At the same time, we strongly encourage creators to use existing parts. Discover the potential they hold. Give them a chance. Co-creation through reuse!

This is one of the reasons why the parts are open source. This removes all boundaries and obstacles that could stand in the way of creative reuse in unexpected contexts! If you truly want to make an impact on sustainability, such a system cannot be developed and scaled with closed parts.

This also explains why this experiment is designed to be decentralised/distributed. The Ikego site is just one place on the internet where parts of the system are displayed and organized. But it is not the only place and not the place you have to use. This is not the place that seeks control over the system. We ask and encourage designers to distribute their contributions wherever they see fit and keep control over them. It is their work! We only ask that universal parts be made completely open. But of course individual sets and products can remain closed and monopolized and be marketed that way.

Pen and paper (parts) are open source. But individual drawings (sets) belong to their creators. This allows commercial power to flow into the growth of the system.

*

But what does all this have to do with SOUP? Read here.

+

Scroll to learn more about how the experiment is currently set

+

A SYSTEM for LOCAL PRODUCTION

🌐

We shoot for high quality and high volume production of Ikego sets and parts across the globe (join us).

But to make the system truly sustainable and circular, we shoot for parts that are easy to produce. In theory the best Ikego part is one that can be made everywhere with just simple and common tools and from local materials.

To enable distributed manufacturing 🦠 we defined TOLERANCE:

↓

CLICK here to learn all about TOLERANCE

Tolerance → local reuse, repair and manufacturing made easy

Ideally, an open multipurpose part will allow local manufacture – even in small workshops. So ideally, for most applications, the part is relatively independent of the material you make it from, and also allows for some inaccuracy in the dimensions of the manufactured part. This is what we call “tolerance”.

Why “material” tolerance? → Because it allows the use of local or leftover material. And also a designer’s creative expression when picking out the final materials and colors.

Why size tolerance? → Because it allows the use of simple tools that are available everywhere. If you need a heavy, expensive machine capable of producing 0.1mm accuracy to make your part work, local manufacture is difficult to achieve, which will make repair or reuse a bit harder. The standard tolerance allows a size deviation of +/- 10mm from the values mentioned in the parts post (It used to be 15 mm in the early experimental phase of the system. But 10 mm proved to be sufficient and causes fewer problems. Some early sets may still work with 15 mm.)

Examples ↓

✼

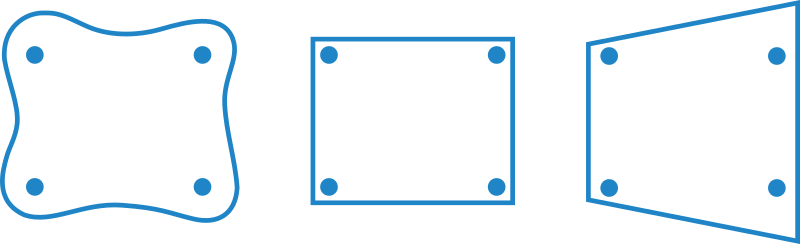

It is important to understand that the number, position and diameter of the holes are not affected by the tolerance! The holes and their exact position in relation to each other make up the identity of the part. Because this is how the parts connect to each other within a grid.

These parts are all the same

The outer shape varies slightly, but the holes are the same size and in the same position relative to each other.

These parts are different

Same board size, same position of holes in the grid, but the holes are of a different size.

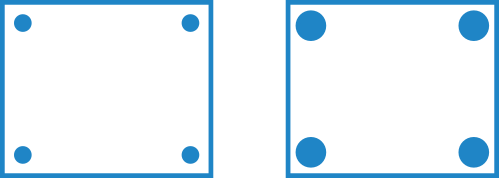

Different parts

These are two different parts. The dimensions are the same and the holes are in the same location, but the holes are different in size.

Same parts

These are the same parts. The dimensions are slightly different but the location of holes relative to each other and their diameters are exactly the same.

✼

Tolerance is a running experiment! We are aware that tolerance may lead to cases where a part does not work in a design with that part (for example when the material is too weak or parts overlap). Le’s see if this really emerges and how big an issue it will be. Ikego is open research. Research with us.

Tolerance enables creative expression. A model is set but the final curves, colors and materials are decided by the designer.

_

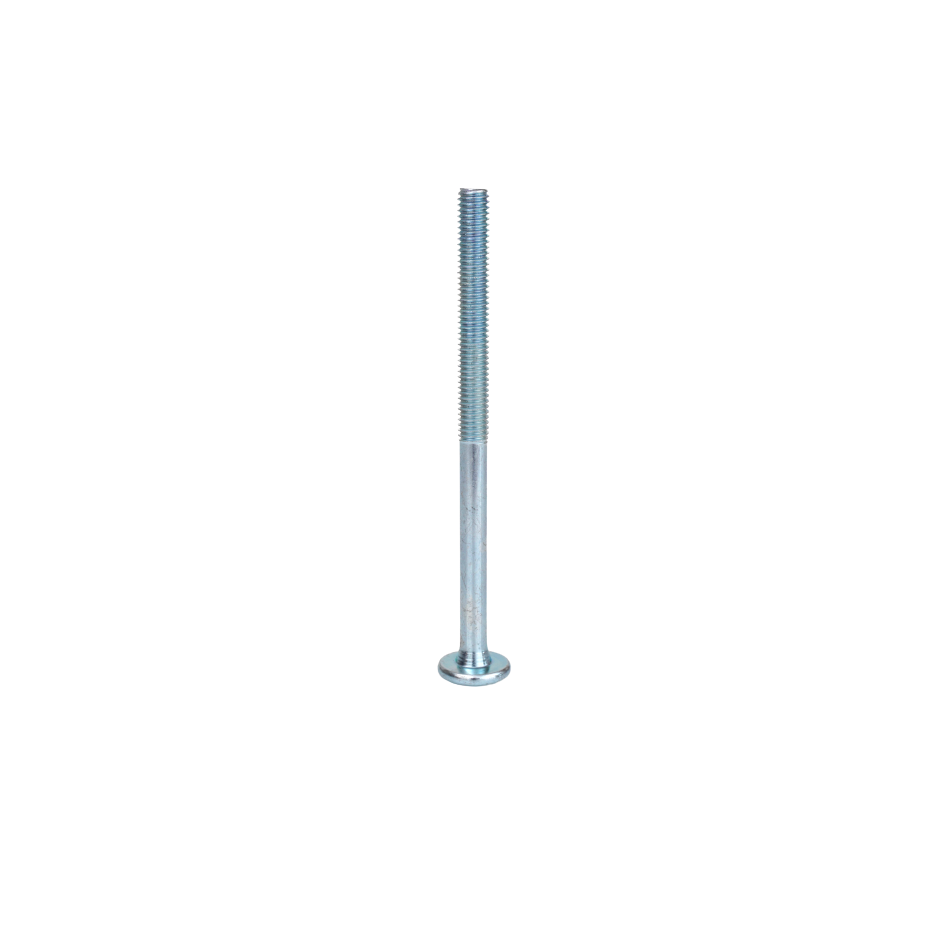

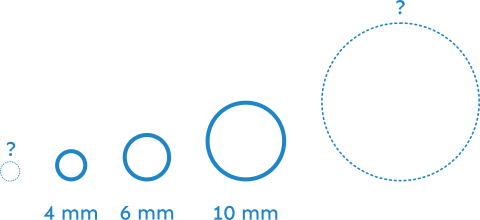

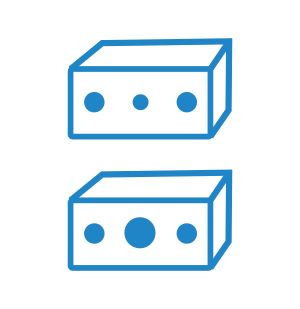

3 Bolt sizes & Hole sizes

The tolerance rule explains why bolts come in these steps:

10 – 30 – 50 – 70 – 90 – 110 – 130 – …

+/- 15mm allows to have all steps in between – for example 14mm.

heads of bolts are free to chose (tolerance)

So far, Ikego designers have worked with 3 different hole & bolt sizes:

10mm – for structures that need to be really strong or to cover M6 cap nuts.

6mm – for M6 screws that are strong enough for furniture such as beds or chairs

4mm – for M4 bolt solutions such as headphones, rucksacks and other small items that don’t need to support a lot of weight.

But this is just a suggestion. Feel free to step out of this.

*

🌿 🌱 🌸 💮 🪷

Aesthetics

If you take into account what was said above about tolerance, it becomes clear that an Ikego set does not have a fixed appearance. The same parts can be made from different materials, curves and radii can be slightly adjusted, and colors or coatings can be selected on site. This always leaves room for skilled designers to add a final creative touch.

↳ Therefor Ikego Sets appear in 3 variants/stages (set stats):

Prototype →

is a rough functional prototype that proves that a set works. A completed research step. It is required to include a set in the catalog | see design brief | This prototype differs from an aesthetic prototype and a manufacturing prototype in that no final decisions on colors and materials have yet been made.

Make →

is a well-made execution (‘interpretation’) of a set by a skilled craftsman picking colors, materials and final shapes. CALL FOR MAKERS: Add a make! Create a really well made make of a set and send us a picture to include in the page. Let’s make the system shine!

Product →

is a professional make that is intended to be sold to customers for money. Either as a one-off-drop or as continuous mass production. See our manufacturer brief. It is important to understand, that while the parts are functionally open a finished product can be closed. Depending on the laws in your region you might be able to protect your specific combination of colors, materials and shapes. Or you can print your trademarked Logo on the set or parts. This will prevent others from copying what you do.

What materials?

Circularity also depends on the materials. So far, we haven’t added anything specific about that. Let’s figure out the multipurpose parts part first. All designs are currently independent of the material. We enable (and encourage) the use of sustainable materials. The door is already open. More about the circularity of materials may be added to the system later. (Feel free to add rules to your design already. And share them. They might become part of the system later. Invent the system with us.)

More

Read our → white paper about “Design with Multipurpose Parts”.

Version 1.0

It’s clear that this is system version 1.0, and we truly believe in an evolutionary approach. Things may change over time. Always ready for new insights! Experiment with us, and let’s find out how we can make improvements together.

Image credits