Basic Info

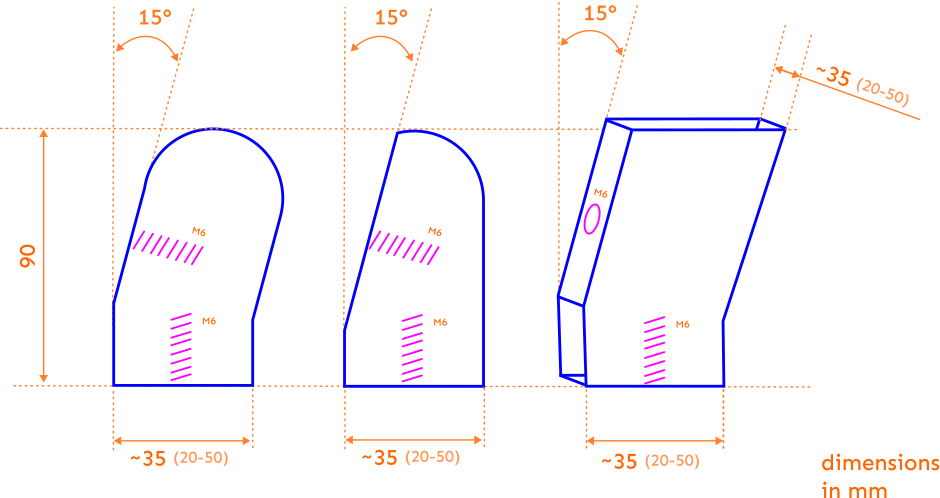

- What is it: a rod with a 15° bend and two M6 insert threads

- Material: strong | standard tolerance (more infos in the “Make” section below)

- Dimensions: 90mm high (fixed), diameter ~35mm, more infos in the drawing and in the “Make” section below | standard tolerance

- Holes: 2 insert M6 threads, see drawing for locations

Get the part

- Buy: Available as local make.

- Make + General info:

-

- The aim of the part is to have a 15° deflection for the Elephant Rods (Ikego parts 095.1-095.5), which also allows elements to be bolted onto the slanted side.

- Therefore, there must be a possibility to screw in an M6 bolt at the bottom and on the side. How this is technically realised depends on the material and manufacturing technique used to produce the part (see material tolerance and the info below)

- The left-hand side of the sketch and the actual photo of the component show the upper end rounded. But this does not have to be the case (see dimensions tolerance). Square ends at the top are also possible. The whole component does not have to be round at all. It can also simply be a wooden angle cut out of a thicker piece, which is shown in the drawing.

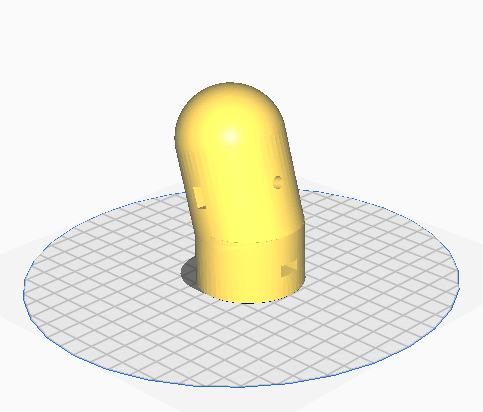

- We provide an STL for one version for 3D-printing (DOWNLOAD external folder, or direct download). The print version we provide fully utilises the dimension tolerance of Ikego; the part in our STL file has a diameter of 50 mm. The screw-in thread in our 3D printed component is produced using a regular DIN M6 hexagon nut, which is simply pushed into the component from the side and then covered with a lock if you like. Detailed instructions after the STL download.

- In addition to 3D printing, we see the following option for manufacturing the part:

- You can simply saw it out square from thicker material and then add regular insert nuts.

- You can take a piece of wooden beam or a thick round bar made of wood and simply remove the 15° angle with a grinding disc. Then simply work in regular screw-in nuts.

- Injection moulding can also work. You create a solid piece of plastic in the right shape then simply cut in the threads – either with a tap or by inserting a screw-in nut.

- Pipes can be sawn at the appropriate angle and welded or glued together again and then the threads can be inserted, e.g. at the bottom using inserts (see Elephant Rods – Ikego parts 095.1-095.5) and at the edge using a tap.

- What other manufacturing options do you see?

Meta

- Introduced by: Lars Zimmermann, via “NoTALKI”

- Original Post, Original Post Backup.pdf

- Open: Shared under IPP 1.0

- Disclaimer

Download an STL (1) from external folder, (2) direct download (note: 3d printing might not be the best way to make this part, depending on the use case)

Download Portal

Most parts have open design and manufacturing files you can download and work with.

More Parts

046.2 – M3 knurled bolt 10mm

008.1 – Plastic threaded rod & bolts ⌀ 10mm

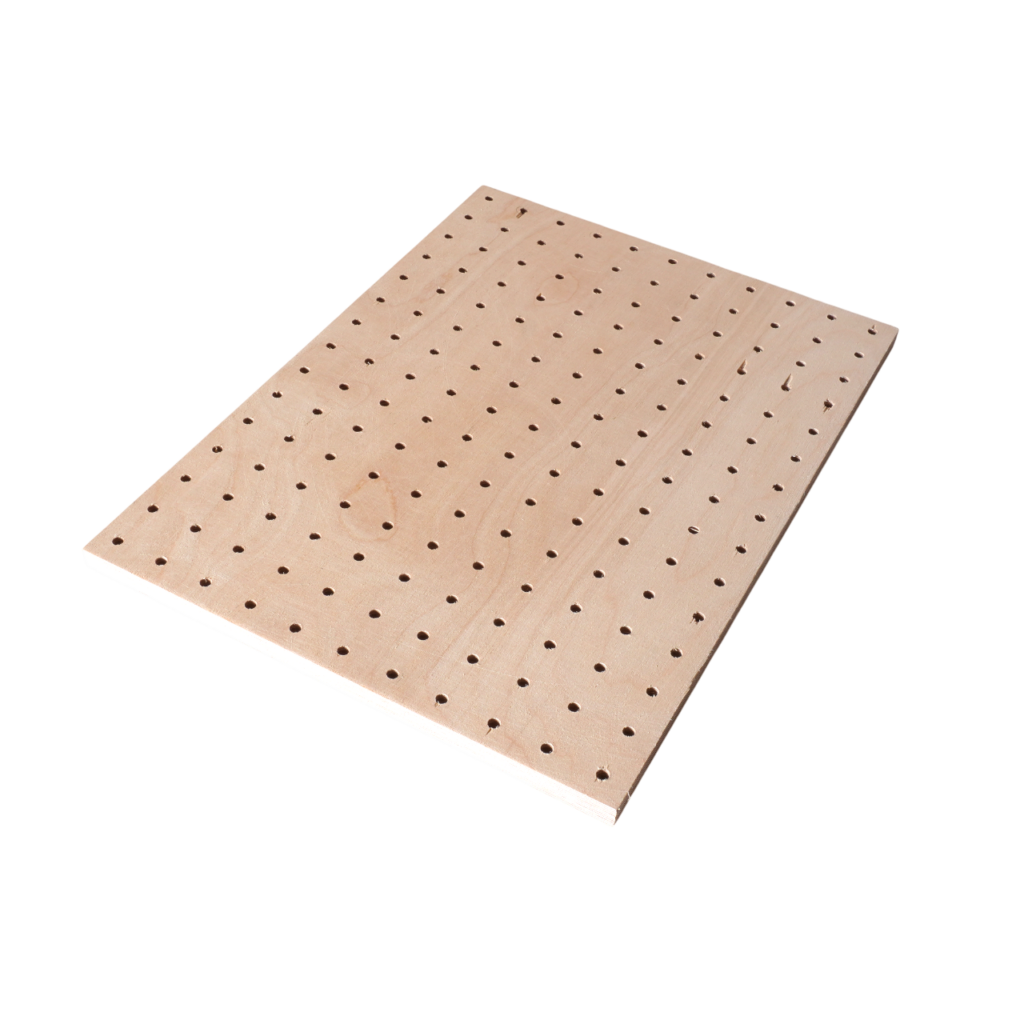

140.2 – Board 450x330mm, ⌀6mm holes

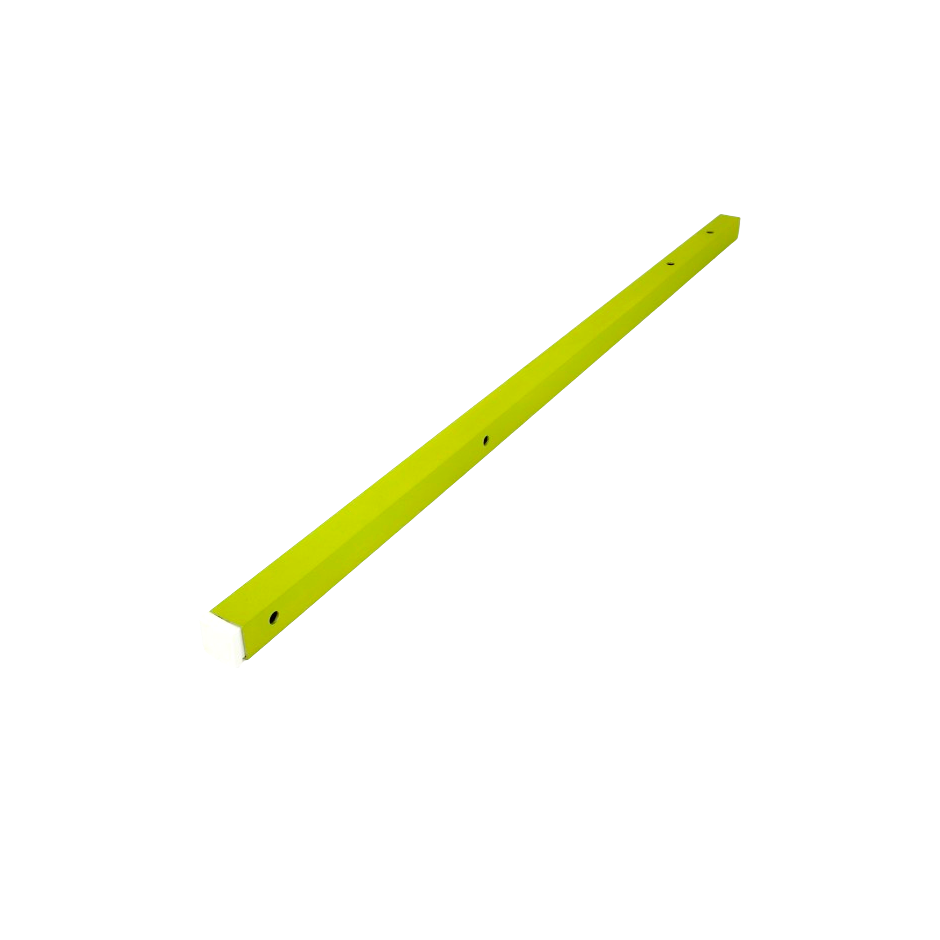

108.1 – Beam ~660x30x30mm

031.1 – Ring ⌀ ~50mm

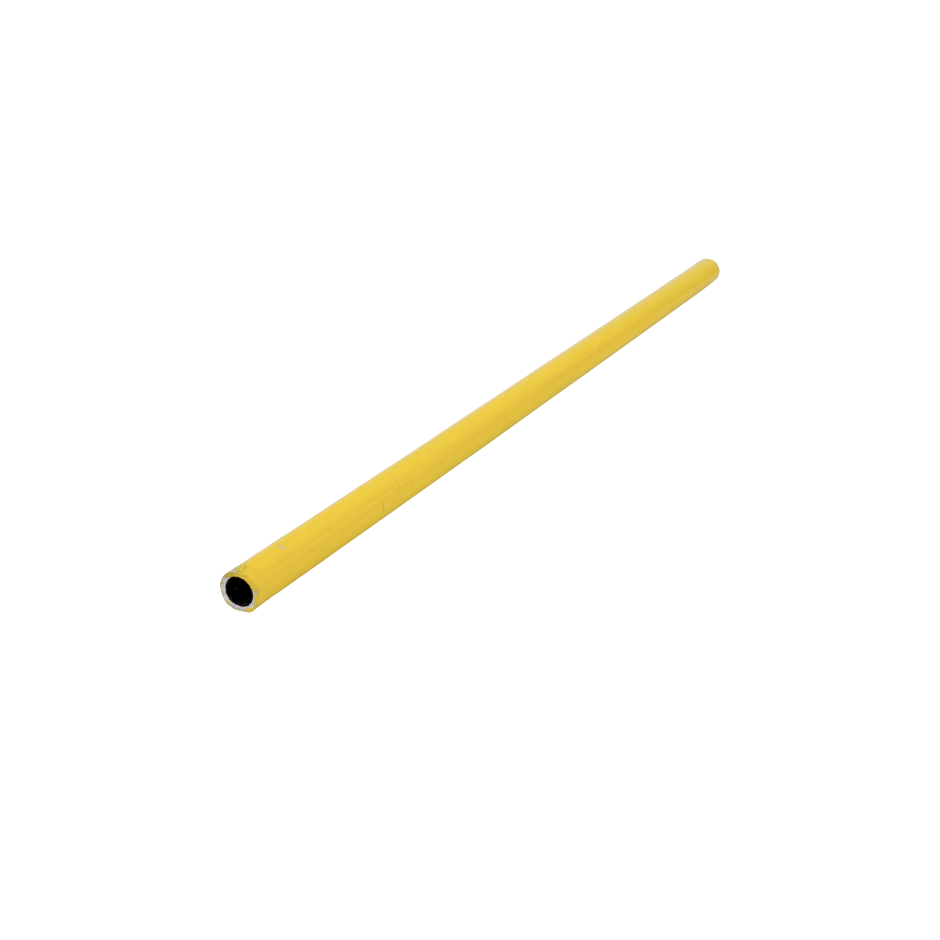

017.1 – Tube 240mm long, ⌀ 10mm

127.1 – “Flappy beam” 360x80x18mm

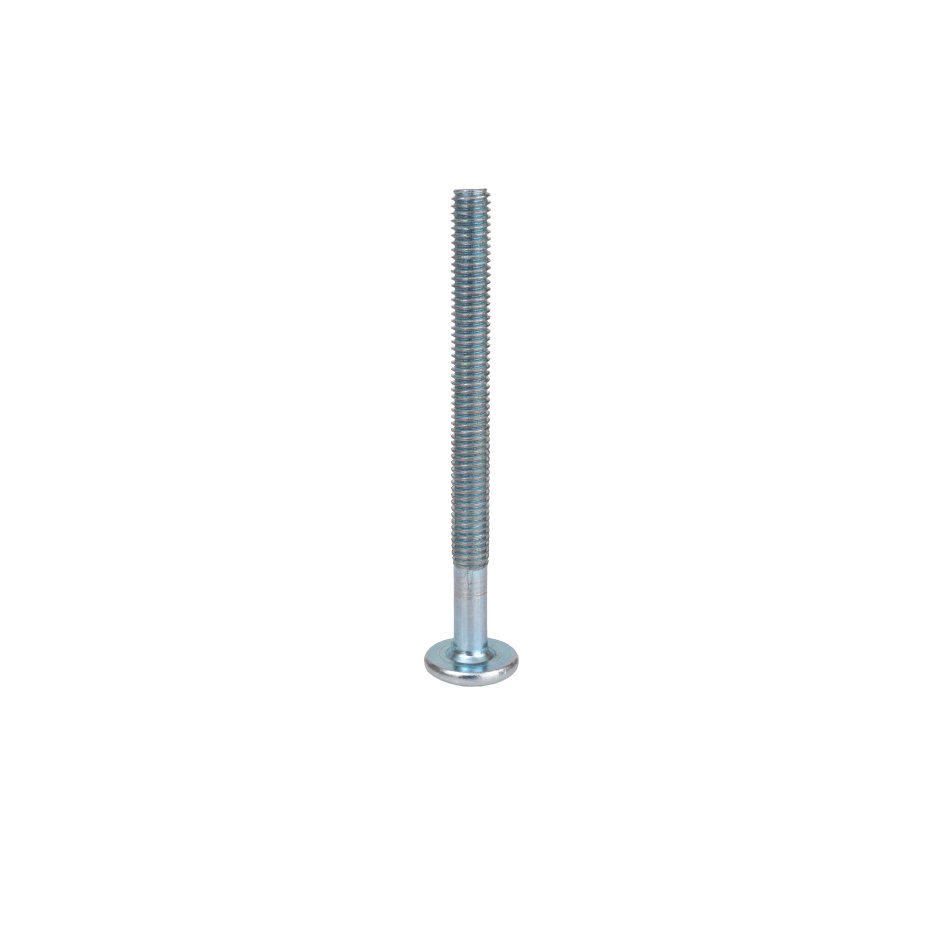

082.2 – M6 bolt 70mm

Play ↻

Do you have any new ideas on how to use these parts? Share it.