Part info

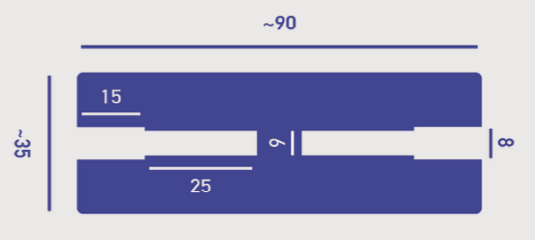

- What: A rod with M6 insert threads on both sides.

- material: strong

- measures:90mm high (fixed!), ⌀ ~30mm. The insert threads are 15mm deep in. There is an extra 25mm space for a bolt after the insert thread. So in total there is room for a 40mm M6 bolt (see sketch below)

Sketch by the designer Parker Haynes

Tolerance

- Size: The length is fixed at 90mm, but the ~30mm diameter is flexible within the standard tolerance

- Material: standard toleranc

Exchangeability

- This part is an Elephant Rod. The original Elephant Rods were introduced by Parker Haynes via the Elephant Shelf. The rods proved to be particularly useful. And so other versions were introduced in addition to the original version (part numbers 095.-). Namely thicker (⌀ ~50mm, part numbers: 129.-) for more strength and contact surface and thinner (⌀ ~20mm, M4 threads, part numbers 112.-) for applications that are exposed to less stress and can therefore save material and volume. The versions may be interchangeable. Depending on how much thickness is needed for the respective set or how much space the design of the set provides for the rods.

Get the part

- BUY

- Globally ↓

- Available as local make.

- Locally ↓

- None so far

- Want to make and sell this part? Add your store

- Make:

- Option 1: The designer Parker Haynes shared instructions for one possible way to make this part. Find the instructions in the original post by the designer or click to download a PDF.

- Option 2: see below

Elephant Rod Making Box

Ikego has various parts in the system that are tubes or beams with internal threads on both sides (095._, 112._, 129._). There are different ways to make them. Some of them are documented here:

1 solid material

Designer Parker Haynes, who originally introduced this type of part into the system (via the Elephant Shelf) has shared a how-to for inserting screw-in nuts into solid wooden (or plastic) poles. See PDF here.

2 pipes with (3d printed) inserts

You can buy tubes put inserts into them. These can be made of solid material and can also be 3D printed. In the meantime, a small collection of directly printable inserts has been created and shared for various pipe diameters. Download STLs for them here:

Remark on 3d printed inserts:

- If the pipe is strong (e.g. aluminium) and you print the exact diameter, you may not need to glue or screw the insert in. You might get lucky and it will just stay in.

- Most of the inserts shared work with a channel for a regular M6 nut. So the thread is metal. Usually there is also a “lock” that helps to keep the nut in place and avoid that it spins and break the plastic. Of course, this part needs to be printed with a strong infill, because the part is holding the nut in place, and if you’re going to put a lot of pressure on it to ensure a stable connection, the 3D printed walls need to be able to withstand that pressure. If the component is not strong enough, the M6 nut will break the walls and start to rotate inside the component.

Introduced by

- Designer: Parker Haynes

- Original post, original post backup (html)

- Open: TPP 1.0

Download Portal

Most parts have open design and manufacturing files you can download and work with.

More Parts

081.1 – Board ~210x390mm

061.1 – Bendable plate ~60x60mm

046.2 – M3 knurled bolt 10mm

086.1 – M4 countersunk bolt 20mm

014.1 – Hook small

005.2 – Disk 151,5 mm 13 holes

055.1 – Rubber band 300mm

144.1 – Wire mesh, not bendable, 300x300mm

Play ↻

Do you have any new ideas on how to use these parts? Share it.